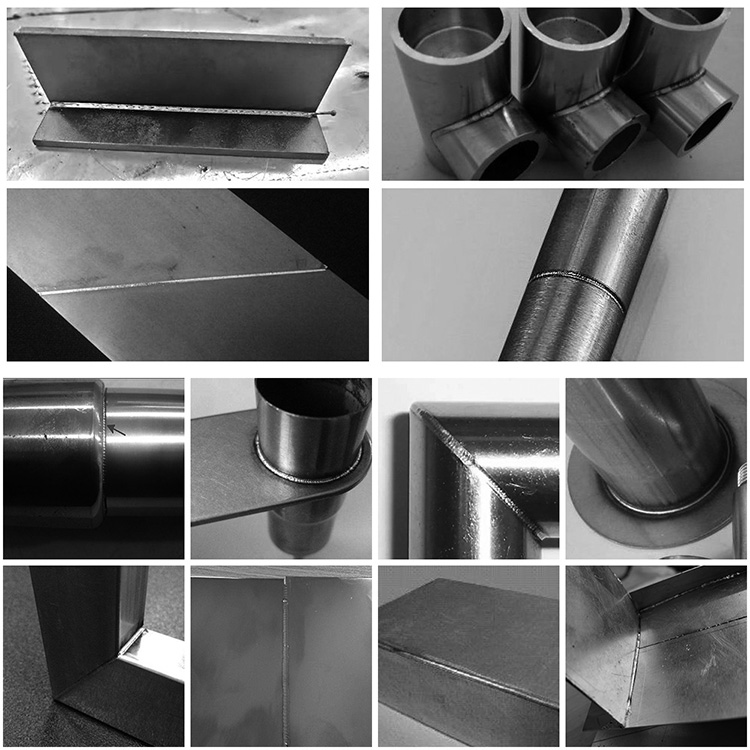

Umshini wokushisela i-laser ungomunye wemishini esetshenziswa emkhakheni wokushisela, futhi ungenye yezici ezibalulekile zokusetshenziswa kwe-welding.

laser material processing technology.Imishini yokushisela, njll., ngabe iyiphi imboni engasetshenziswa kuyo imishini yokushisela nge-laser?Nazi ezine

izimboni zokufaka izicelo zemishini yokushisela i-laser.

Izinhlelo zokusebenza zokukhiqiza

Imishini yokushisela i-laser isetshenziswa kabanzi ekwakhiweni kwezimoto ekhaya nakwamanye amazwe.Esikhathini esidlule, imishini yokushisela laser ye-CO2 yayisetshenziswa

e-Japan esikhundleni se-flash butt welding ukuxhuma amakhoyili ensimbi ezimbonini.Esifundweni se-ultra-thin plate welding, isibonelo,

ama-foil anogqinsi olungaphansi kwama-microns ayi-100 awakwazi ukushiselwa, kodwa i-YAG laser welding enamagagasi okukhiphayo akhethekile Impumelelo, i-laser welding

esikhathini esizayo esibanzi

Inkambu ye-powder metallurgy

Ngokuthuthuka okuqhubekayo kwesayensi nobuchwepheshe, ubuchwepheshe abaningi bezimboni banezidingo ezikhethekile zezinto zokwakha, nezinto zokwakha

eyenziwe ngobuchwepheshe bendabuko ngeke isakwazi ukuhlangabezana nezidingo.Umshini wokushisela we-laser ungene emkhakheni wokucubungula we

izinto zokwakha ze-powder metallurgy, ezilethe amathuba amasha entuthuko ekusetshenzisweni kwezinto ezisetshenziswayo ze-powder metallurgy.Ngokwesibonelo, idayimane

ishiselwe kusetshenziswa i-powder metallurgy material ehlanganisa izindlela ezijwayelekile zokubrasa.Ngenxa yamandla okubopha aphansi kanye nendawo ebanzi ethinteke ekushiseni,

ikakhulukazi uma ingakwazi ukuzivumelanisa nezinga lokushisa eliphezulu kanye nezidingo zamandla aphezulu, kuzokwenza ukuthi i-solder incibilike futhi iwe.Ukusebenzisa i-laser

umshini wokushisela ungathuthukisa amandla okushisela kanye nokumelana nokushisa okuphezulu.

Imboni yezogesi

Imishini yokushisela i-laser isetshenziswa kabanzi embonini ye-elekthronikhi.Ngenxa yendawo encane ethinteke ukushisa, ukugxila kokushisa okusheshayo nokuphansi

ukucindezeleka okushisayo kwe-laser welding, izinzuzo ze-laser welding ziboniswa ekufakweni kwamasekethe ahlanganisiwe kanye nedivayisi ye-semiconductor

izindlu, kanye ne-laser welding nayo isetshenzisiwe ekuthuthukisweni kwamadivaysi e-vacuum.Noma ugqinsi lukathayela olunwebekayo olunezindonga ezincane

ipuleti ku-thermostat ingu-0.05-0.1mm, okunzima ukuxazulula ngezindlela zendabuko zokushisela.I-TIG welding iyasebenza futhi isetshenziswa kabanzi ngenxa

ekungeneni kalula kokushisela, ukuzinza kwe-plasma okubi kanye nezici eziningi ezinethonya..

Imboni yezimoto

Njengamanje, umugqa wokukhiqiza umshini we-laser welding uvele ngezinga elikhulu embonini yokukhiqiza izimoto futhi usungomunye

wempumelelo encomekayo yemboni yokukhiqiza izimoto.Abakhiqizi bezimoto abaningi basebenzisa i-laser welding kanye namasu okusika.Amandla aphezulu

izingxenye zensimbi ezishiselwe nge-laser ziya ngokuya zisetshenziswa ekwakhiweni kwemizimba yezimoto ngenxa yezakhiwo zazo ezinhle kakhulu.Ngenxa yomthamo omkhulu

kanye nezinga eliphakeme lokuzishintsha embonini yezimoto, imishini yokushisela i-laser izothuthuka ibheke kumandla aphezulu kanye ne-multiplexing.

Isikhathi sokuthumela: Sep-28-2022